Hand Woven

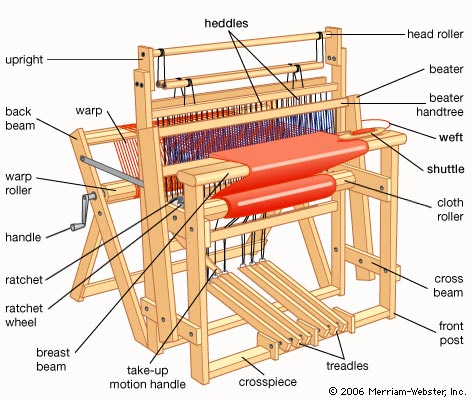

Weaving is an age old method of textile production in which two distinct sets of yarns or threads are interlaced at right angles to form a fabric or cloth, and the simple equipment that facilitates this process is called the 'loom'. Loom is the basic equipment for hand weaving, and on basis of their structure and technique, there are several types of handlooms or semi-automatic looms.

Weaving is an age old method of textile production in which two distinct sets of yarns or threads are interlaced at right angles to form a fabric or cloth, and the simple equipment that facilitates this process is called the 'loom'. Loom is the basic equipment for hand weaving, and on basis of their structure and technique, there are several types of handlooms or semi-automatic looms.

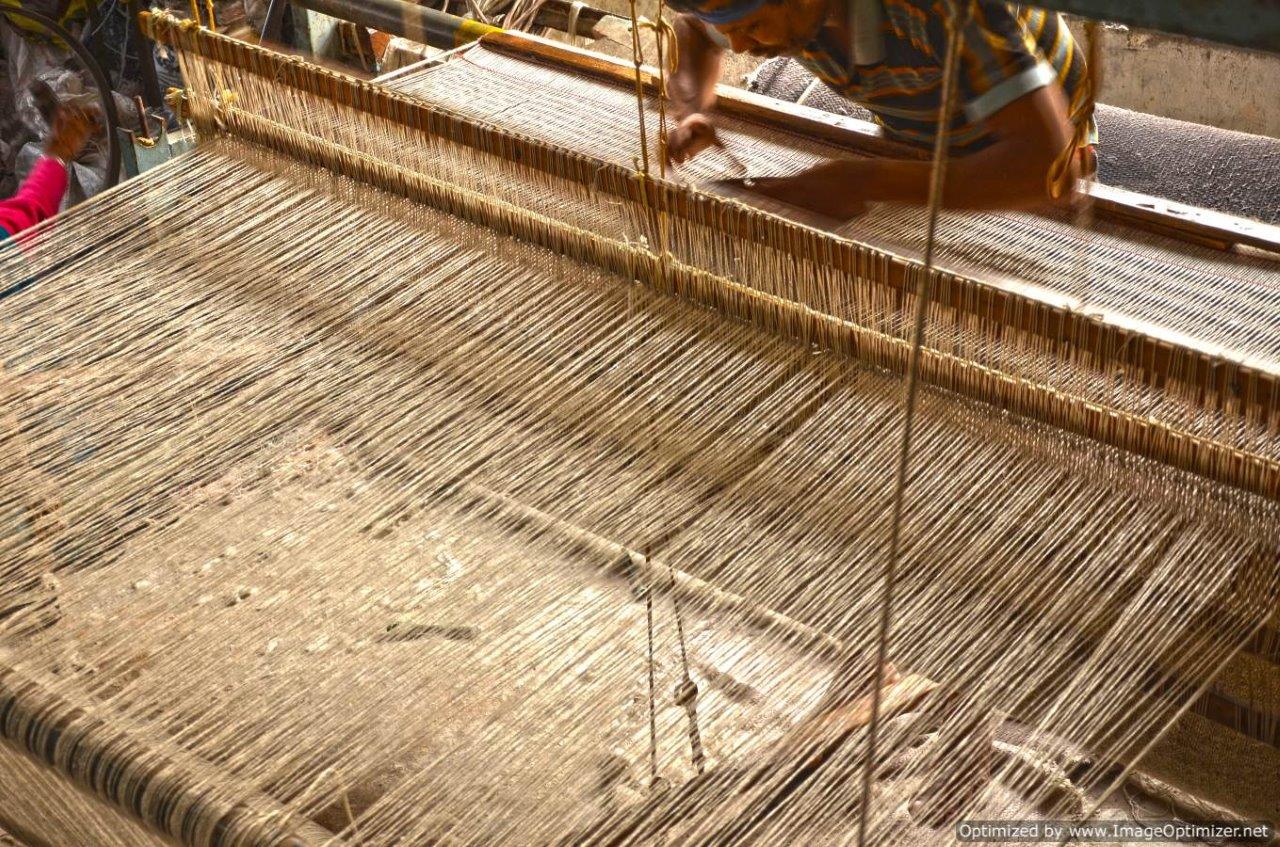

The yarn (dyed or undyed as required for the design), in hank form is wind over bobbins with the help of 'charkhas' (a manual spinning wheel), thus transforming it into linear form. This process enables the laying out of yarn length for weaving. A simultaneous process carried out is 'warping', which is creating the base yarn that runs along the length of the fabric. It is attached to the loom lengthwise before the weaving begins. The warping process converts the hank yarn into a linear form to give the length on the loom. It is done on a huge drum (called Taana machine) and the width and desired quality of the product is decided at this stage. The drum also helps to calculate number of threads and the length of the warp.

While weaving carpets, the artisans weave the weft, creating the different patterns & textures. To create the pile, the yarn is wrapped around a special flat iron rod during the weaving process and then cut to ensure equal height. This technique permits a wide range of finishes, from simple and delicate short-strand pile, shag rugs to more elaborate loop pile involving various yarns. If the top of the loop is cut (manually with a blade), then we get cut pile carpet. If left as it, then we can have loop pile carpets.