Hand Tufted

'Tufting' is an ancient method of creating rugs & garments. It is a type of weaving technique wherein strips of cloths, threads or yarns are pushed through a base material and then glued together for a strong hold. Tufting makes use of a tool called ‘tufting gun’ so as to make the process easier & much faster than knitting each tuft. This tool holds the material in place and then pushes through the primary base material.

'Tufting' is an ancient method of creating rugs & garments. It is a type of weaving technique wherein strips of cloths, threads or yarns are pushed through a base material and then glued together for a strong hold. Tufting makes use of a tool called ‘tufting gun’ so as to make the process easier & much faster than knitting each tuft. This tool holds the material in place and then pushes through the primary base material.

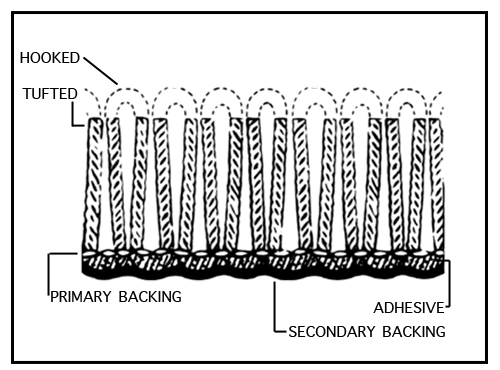

In case of rugs & carpets, the outline of the design is first imprinted on a cloth (known as canvas) as per the actual size, and then stretched over & fixed on a metal frame which has nails all around. The tufter (i.e. the person who does the tufting) keep the design artwork marked with the yarn placements in front and uses the tufting gun to insert the yarns onto the canvas i.e. the primary base. Depending on the design, the top side which is called as 'pile' can either be cut or left as a loop or a combination of both, and also the height of the pile can be controlled by this tufting gun. After the tufting is complete, a cotton mesh is placed at the back and latex is applied to it so that the tufts don’t fall off the canvas and are left for drying.

Sun drying is ideal, but due to adverse weather conditions like rain or fog etc, large scale production facilities uses heat chambers. Finally, another coat of latex is applied and a final backing of cotton canvas or any other synthetic fabric is done (to give a protective covering). After this, the edges hand-sewn, the design elements are made sharper by manual clipping with scissors, and the rug is ready.