Pitloom Weave

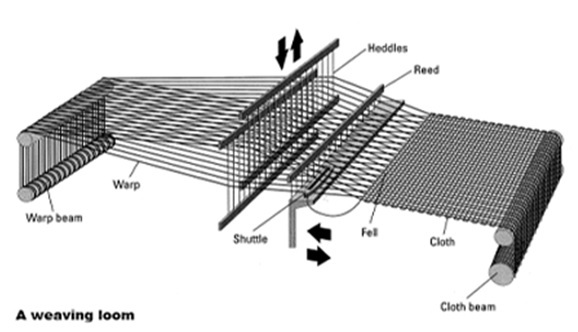

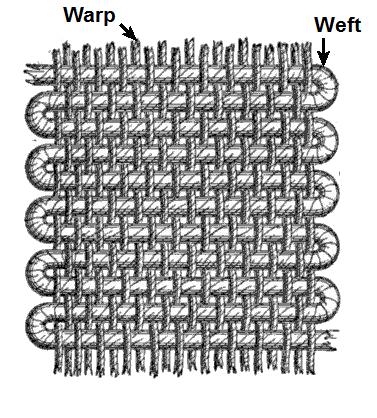

As the name suggests, 'Pit Loom' is a type of loom which is fit in a pit where the artisan makes the rug through the use of pedals, and normally the base of pitloom is more strong than handloom & can go without using latex. It is used mainly for producing thin flat-weave rugs (but can also make chunky flat weaves & shaggy pile rugs); these rugs do not have a pile, and they are often reversible. In working, it simulates the handloom, the only difference is its size & height. It is called pit loom because of the pit below the loom, which is used for the shedding operation. The space or gap between the two layers of the warp threads is called shed. A shed is produced by means of healds or harnesses. The warps are maintained in tension between two beams, in between healds are used with help of two levers, these healds are connected with two paddles situated inside the pit, which are used for the shedding. Wefts are inserted manually inside the shed. The warp threads are divided into two layers or parts one above the other, for the passage of the shuttle with a pick of weft.

Rest processes like yarn opening, warp making etc remains same like producing other loom rugs.